At D&D Laboratory Sdn Bhd, we pride ourselves on being a premier supplier of analytical instruments tailored specifically for the mining industry. Our extensive range of cutting-edge scientific instruments, including Atomic Absorption Spectroscopy (AAS), Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES), Inductively Coupled Plasma Mass Spectrometry (ICP-MS), Microwave Digestive Systems, Thermogravimetric Analysis (TGA), and Fusion Systems, are designed to meet the rigorous demands of mineral analysis and environmental testing. Each instrument is engineered to provide precise and reliable results, ensuring that mining operations can maintain compliance with environmental regulations while optimizing resource extraction processes.

Our AAS and ICP-OES systems offer unparalleled sensitivity and accuracy for trace metal analysis, essential for assessing ore quality and environmental impact. The ICP-MS provides advanced capabilities for multi-element detection at ultra-trace levels, making it indispensable for comprehensive geochemical profiling. Meanwhile, our Microwave Digestive Systems facilitate efficient sample preparation, ensuring that even the most challenging matrices are analyzed effectively. The Thermogravimetric Analysis system allows for detailed thermal characterization of materials, providing insights into composition and stability. Lastly, our Fusion Systems enable seamless sample fusion for XRF analysis, enhancing the accuracy of elemental quantification. By integrating these advanced technologies into your laboratory operations, you can enhance productivity and ensure the integrity of your analytical results.

Microwave Digestion System

Microwave digestion systems use microwave radiation to rapidly decompose samples in sealed vessels for elemental analysis (e.g., ICP-MS). Reduces processing time vs traditional methods, minimizes reagent use, and ensures safety via automated controls. Ideal for environmental, food, pharmaceutical, and geological testing.

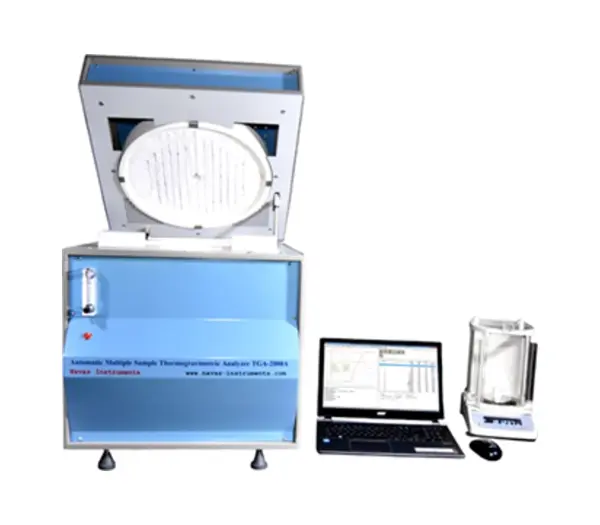

Thermogravimetric Analysis

Measureing the weight changes of materials (e.g., coal, iron ore, minerals) under controlled temperature to determine composition, thermal stability, and decomposition behavior. It quantifies moisture, volatile matter, ash content, and loss on ignition, critical for quality control in processes like coal classification, iron ore processing, and mineral characterization. TGA helps optimize industrial workflows (e.g., calcination, combustion) and ensures compliance with safety and efficiency standards by analyzing material responses to heat.